Commercial Sous Vide Solutions from fusionchef

The fusionchef™Pearl offers all the core functions you need to master professional sous vide cooking. Combine this powerful, commercial-grade circulator with your choice of bath tank sizes, ranging from 3.4 gallons to 15.3 gallons. Don’t want a bath tank? No problem. Our bridge mounted Pearl pairs easily with a Cambro.

Shop All Pearl

Diamonds are a girl’s and a chef’s best friend. Automate your sous vide cooking with 15 customizable pre-sets, three timers, and data logging software for HACCP compliance. This fail-proof approach to sous vide is perfect for busy, high-volume kitchens. Bath tank sizes range from 3.4 gallons to 15.3 gallons. You can also bridge-mount our fusionchef™Diamond circulators directly on a Cambro.

Shop All DiamondShop bags, sealers, tank lids, temperature probes, travel cases, retaining grids and everything you need to make the most of your sous vide cooking.

SHOP ACCESSORIES

Follow these simple steps to unleash the unbeatable results and uncompromising consistency of sous vide commercial cooking.

Dial the cooking time and target temperature into your fusionchef™ Pearl or Diamond Immersion Circulator and allow enough time for the bath to come up to temperature.

Choose fresh, raw ingredients. The sous vide method is simple and requires little preparation other than safe food handling and portioning. Just add your favorite herbs, spices, and oil or butter as desired.

Vacuum seal the prepared food (below 38°F, 4°C) to lock in natural flavors, seasonings, nutrients, and juices.

Place the vacuum-sealed product into your fusionchef™ insulated stainless steel tank (or plastic cambro) for the predetermined cooking time.

The timer on your fusionchef™ Pearl Immersion Circulator or the temperature probe on your fusionchef™ Diamond Immersion Circulator will alert you when the target internal temperature is reached or your cooking process is complete.

If you don’t plan on serving the product right away (and want to get ahead and gain control over your prep process), cool it in a bath of ice water or a commercial grade blast chiller and store it until service.

Just before serving, return your chilled bag to the water bath to heat the dish to your target serving temperature.

Once the food has reached the target doneness, remove the bag from your fusionchef™ water bath. Let it rest and then simply sear, grill or sauté for additional texture.

With less time spent monitoring the cooking process and more freedom for creativity and presentation, you can really inspire your guests.

Curious about the sous vide process, its benefits, or why to buy from fusionchef™? Check out our Sous Vide FAQs

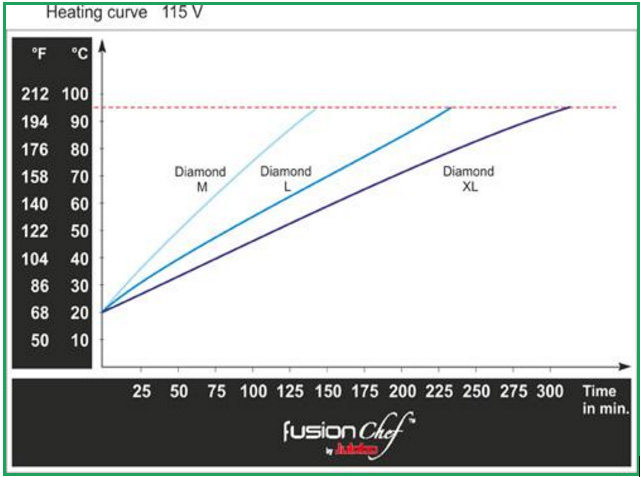

The heating time of your bath depends on what your bath is made of and what the initial water temperature was. An insulated vessel (such as our stainless steel tanks) is your best bet for combating temperature loss and increasing the speed at which your tank gets hot. Based on the assumption that the initial temperature of the water is 64.5 °F (18 °C), the heat-up times of the water for the Diamond M, L and XL immersion circulators are as follows:

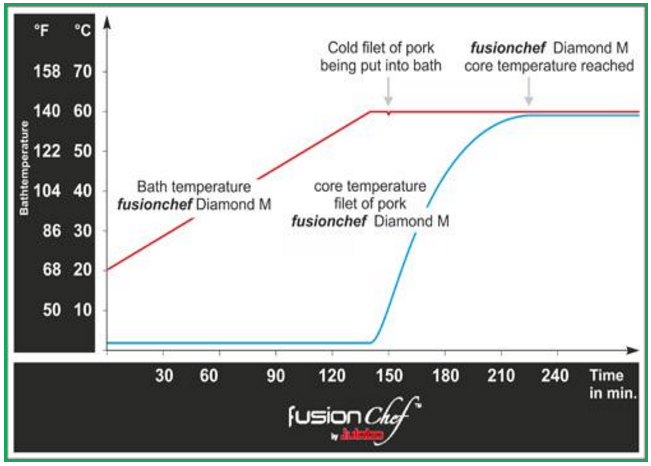

The following graph shows the rise in both water bath temperature (using the 7 gallon Diamond M immersion circulator) and rise in the core temperature of a 1.5” thick tender cut of meat (pork) as cooking time progresses. The laws of thermodynamics can make answering this question tricky; therefore, we have removed the guesswork by integrating a real-time internal temperature probe into our diamond model. It will not only log your data for HACCP, but can also be set to alert you when your product is up to temp.

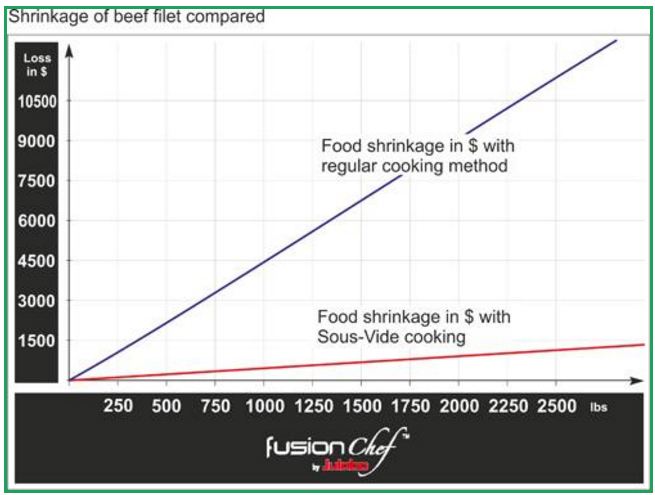

The sous vide method results in significantly less moisture loss and shrinkage in all forms of food products. With tender proteins, the difference is clear: 5% shrinkage (sous vide) versus 40% shrinkage (conventional cooking methods).

The following graph compares the shrinkage of beef filet (price per lbs of beef: $13.00):

To ensure that the bath maintains a uniform temperature and that the water is able to circulate properly, never pack it completely with food. Reference the following chart to compare water bath volumes with their acceptable filling quantities.

| XS Bath Tank: 3.4 gal (13 l) |

up to about 13.2 lbs (up to 6 kg) |

| S Bath Tank: 5 gal (19 l) |

up to about 19.8 lbs (up to 9 kg) |

| M Bath Tank: 7.1 gal (27 l) |

up to about 28.7 lbs (up to 13 kg) |

| L Bath Tank: 11.6 gal (44 l) |

up to about 46.3 lbs (up to 21 kg) |

| XL Bath Tank: 15.3 (58 l) |

up to about 63.9 lbs (up to 29 kg) |

Our chef recommends using three fusionchef™ units when working with different cooking temperatures (e.g., meat, fish and vegetables) for ultimate efficiency.

Another option is to use the core temperature sensor available with the Diamond Immersion Circulator. You can heat up the unit to the desired temperature for one food item, and then monitor another food with a lower cooking temperature via the core temperature sensor and the core temperature alarm. When this secondary food with the lower cooking temperature (the one you’re monitoring with the core temperature sensor) has reached its target temperature, take it out of the water bath and continue cooking the higher-temp food.

The integrated pump installed in all fusionchef™ by JULABO immersion circulators has a capacity of 3.7 gal/min. This guarantees proper circulation of water for a temperature stability of ± 0.01°F (± 0.01°C) in the entire water bath or cooking vessel.

fusionchef™’s powerful 3.7 gallon a minute pump guarantees fast heat-up time, and even faster kick-back time after you load it up with the product you plan on cooking. Our pumps will also allow you to circulate larger volumes of water only using one circulator!

In general, there are two types of vacuum machines: the professional chamber machine and the household vacuum machine without a chamber.

For professional use in restaurants and catering, we highly recommend a chamber vacuum machine because it is a tool like no other. The applications are endless and include vacuum smoking, product compression, deaeration, speed tenderization, and vacuum marination. *Using a vacuum machine in a professional setting requires a HACCP plan.

For sous vide cooking at home, a vacuum machine without a chamber is perfectly suitable. It saves space, it’s effective and it’s less expensive than a chamber machine.

In general, there are three commercial types of vacuum bags used for cooking sous vide. They include channeled bags: for freezing and preservation, smooth: for cooking (not preservation), and a channeled/smooth combination: best option for preservation and cooking.

Sealed-edge bags (also called 3-side sealed bags) are sealed on three sides. These bags are perfectly suitable for sous vide cooking.

Pay close attention to the temperature resistance of your bags! It should comply with your cooking temperature (104°F – 212°F / 40°C – 100°C) and should not be compromised by cooling or shock-freezing. Cooking sous vide requires the use of BPA-free bags to avoid the possibility of contaminating your product with carcinogens.

fusionchef™ by JULABO engineers lab-grade equipment for ultimate durability, flexibility and precision in the kitchen. These products are designed for continuous operation and frequent use. While a specific maintenance service is not necessary, our experts recommend that you follow a few basic instructions:

I. Change the water of your water bath or cooking vessel regularly.

II. Clean the entire sous vide unit regularly, including heating coils and air intake.

III. Use only cleaning products specialized for stainless steel.

IV. Descale your sous vide equipment with the fusionchef™ by JULABO descaling agent at least once a month. This is especially critical if you’re using hard water.

All food product and cooking techniques comes with a modicum of associated risk if handled improperly. Sous vide is no different. Proper food safety precautions and procedures must be followed to prevent serious health hazards. Pay close attention to time and temperature abuse when preparing your product for the tank. Keep in mind that most microbes are killed at a temperature of 131°F (55°C) and that bacterial growth can be reduced by consuming immediately or by cooling the cooked food to 37.4°F (3°C).

There is no specific, scientific proof correlating serious dangers with the sous vide method. Just make sure that you’re always using fresh ingredients and complying with applicable hygienic requirements and food safety standards during food preparation.

Additional questions or concerns?

The chefs, engineers and scientists at fusionchef™ by JULABO will be happy to answer additional questions or alleviate any concerns you may have. Contact us or call our customer service department at +1-610-231-0250 or +1-800-458-5226 anytime between 8:30 AM to 5:00 PM EST, Monday through Friday.

Precise temperature control prevents over-cooking, under-cooking, and food waste. Our products allow you to automate your cooking, preparation, and execution through advances in heating and cooling technologies. fusionchef is a division of JULABO USA, the experts in laboratory and industrial temperature control. Our culinary tools make it easy for you to deliver high-quality food, beverages, and frozen desserts without fail. Even the most discerning diners will be impressed.

Shop Our Products